Swaging Tool Selection

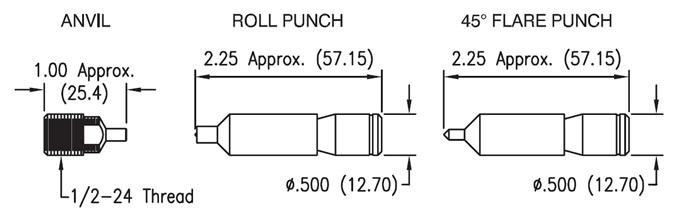

Where appropriate, the part numbers of recommended swaging tools are specified, and in many cases we offer a choice of Roll Punch or Flare Punch. generally we recommend a flared swage where the component will be soldered to an etched pad on the swaged side of the board. Roll swaging is commonly used where the component is to be installed on a plain board.

The flared swage is mechanically weak prior to soldering; but after soldering, the solder filllet provides a reliable electrical and mechanical connection. The flare swage is not intended to make the swaged component more than finger tight prior to soldering.

By comparison, the rolled swage is much stronger; however, a void may be formed underneath the swaged collar where flux could be entrapped or air may be present which could cause blowholes if soldered.